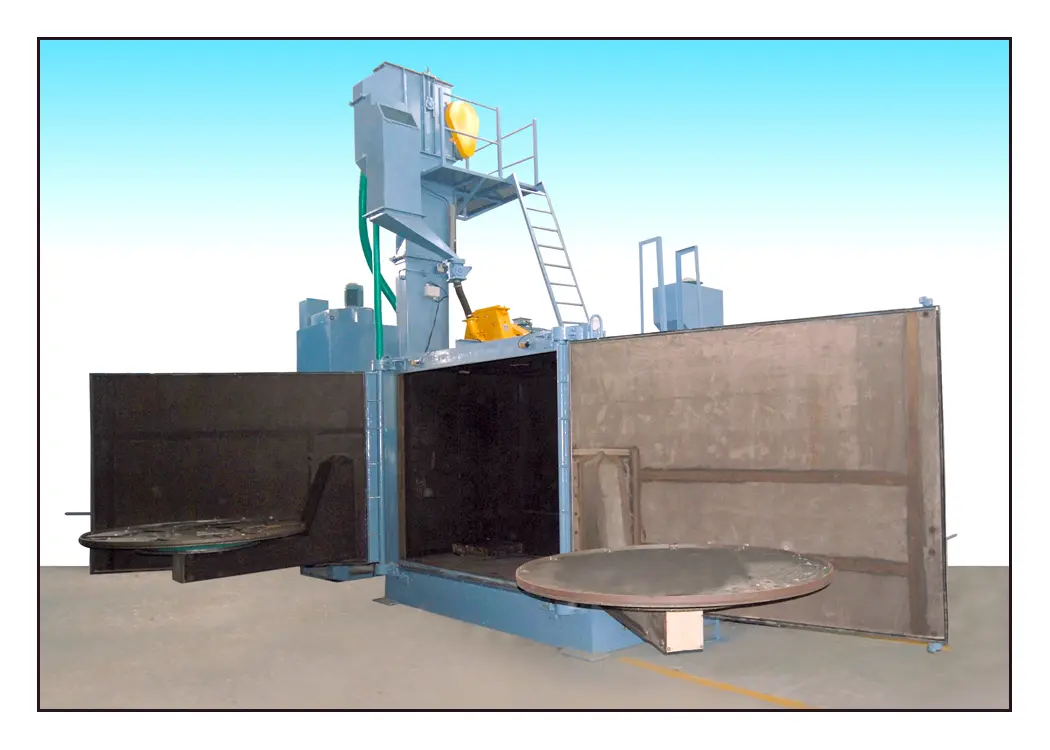

Rotary table shot blasting machine mainly consist of blasting chamber, blast wheel, ,screw conveyor, bucket elevator, separator, dust collector, electric control system and others. Rotary table shot blasting machines are universal shot blasting machines that may be used for blasting a wide variety of workpieces, such as welded constructions, castings, forgings, etc. A carefully planned position of turbines provides the optimum efficiency and uniformly cleaned surface of all sorts of workpieces, irrespective of their shape and size.

Workpieces are loaded on a table or on satellites fixed to a table prior to entering the blast chamber. There is no movement between the work and no part-on-part contact. Several workpieces can be blasted. The table rotates in the shot blasting chamber, providing the optimum cleaning of workpieces.

Rotary table type shot blasting machine can descaling of forged or heat treated parts, desanding of ferrous and non-ferrous metal castings, deburring of metallic and non-metallic parts, deflashing of die cast parts and contaminant removal.

Rotary table shot blast machine is used for shot blasting of various part shapes and dimensions, casts and forged parts, pressed parts, steel and non-ferrous metal parts and parts made from fragile materials. Shot blast machine designed by our company does cleans surface, desand casting, consolidate the surface (micro handling), roughing the surface before painting, etc. Rotary table blasting machines are especially suitable for use in small series and individual part production.

Rotary table shot blast machine is equipped with one or two blast wheels, depending on model size. Standard table work size are from 650 mm to 2,400 mm and can process work pieces of max 1,500 mm height. Standard equipment of larger shot blasting machines includes: PLC, display, timer, automatic or manual mode, automatic start-up of blasting wheels, working-hours counter, etc.